- BUSINESS

- MAINTENANCE & REHABILITATION

MAINTENANCE & REHABILITATION

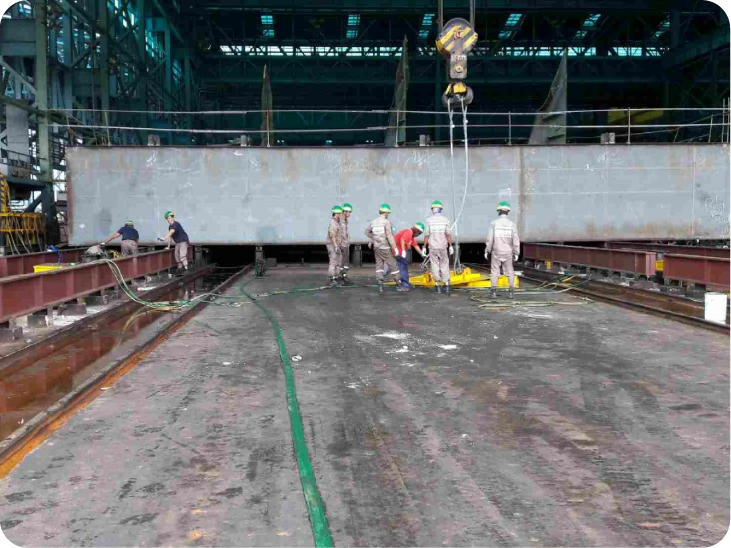

Maintenance in a shipyard encompasses regular activities aimed at keeping the vessel or an offshore platform

in optimal working condition. This includes preventive maintenance tasks such as inspections, cleaning,

lubrication, and minor repairs, all intended to identify and address wear and tear before they develop into

major issues. Effective maintenance also ensures that the ship’s systems, machinery, and equipment continue to

operate efficiently, safely, and in compliance with regulatory standards. In line with this, maintenance

activities are generally categorized into scheduled maintenance, such as annual dry-docking, and unscheduled

maintenance, which is carried out in response to unexpected failures or breakdowns.

Rehabilitation in a shipyard refers to the process of restoring and upgrading a vessel or an offshore platform

that may have suffered damage, deterioration, or obsolescence over time. It consists of structural repairs,

system overhauls, and enhancements to bring the ship or platform back to operational standards. Also, this

procedure often involves significant repairs to hulls, machinery, electrical systems, and safety equipment. It

may also include upgrading of a vessel to meet current regulatory standards or to improve performance and

efficiency.

STACK IN POWER STATION

GAS PIPE IN POWER STATION

Projects

Learn more about the projects we've completed.

Check them out now.

Contact Us

Need help or have questions?

Reach out and we’ll respond quickly and clearly.